WELCOME TO

Burners Reactors Company

Mixed Fuel Vacuum Burners Reactors

Two-Staged Vacuum Burner

二级真空燃烧器

混合燃料真空炉

двухступенчатая вакуумная горелка

World Patented Technology

Potentialities of the invention

Burners Reactors Blue Technology

It can be designed in infinite other shapes and sizes for different applications.

There are already over 40 different construction drawings developed with compressed air only instead of a secondary natural air inlet.

Potentialities of the invention

Zero Emissions

It is 100% stoichiometric, meaning there are no carbon and no NOx emissions, this technology is 100% ecologic, since the amount of air introduced is totally under control and the exact molecular amount needed.

Potentialities of the invention

No Starting Smoke

Unlike most boilers that smoke at their start, this technology starts and smokes as much as a home gas kitchen.

Potentialities of the invention

Multi-Fuels

It can burn ANY fuel, like glycerin (a 10% leftover of the biodiesel that creates acrolein at 400º C and is being disintegrated at 900º C during 3 seconds given by the rotation of the gases), burned oil from cars, and even the most difficult liquid fuels and gases in infinite combinations

Potentialities of the invention

Atmosphere Decontaminant

It has the potentiality of cleaning the atmosphere from carbon, even from the air that goes through the burner, and other contaminants already in the air we all breathe from a 12 km (7 miles) high atmosphere, and our descendants would too.

Potentialities of the invention

Atmosphere Restauration

By eliminating the contaminants, nature can have a chance to close the Ozone hole.

Potentialities of the invention

Water to Fire

It uses Oxyhydrogen generated by water electrolysis, snow or rain to create a 1200º C flame at which fuels are pulverized and immediately crack. HHO can be increased up to 80% for other specific applications of this technology like desalinators and boilers. As safe as any other actual technology

Potentialities of the invention

Boilers

Easy to adapt to existing boilers by just replacing the doors of the 1768's Mr. Watt old system of contaminating burners. A no pipes boilers has been already designed.

Potentialities of the invention

Productivity

Less boiler stops due to bad combustion and no more damage to the boilers due to ancestral methods whose result are carbon incrustations. The inlet gases to the boiler are already clean as it can be seen in the video.

Potentialities of the invention

Fuel Savings

Due to the higher temperature of 1200º C, if a nowadays burner works 24 hours at 900º C, this one will work 18 hours to achieve the same quantity of heat. This fact, plus the carbon burned, instead of being thrown to the atmosphere ends up with saving from 20% to 60% depending on each fuel.

(As written in the cost table of the patents of all countries)

This savings at 40% of the cost, increase percentage of fuel reserves by 40%.

Potentialities of the invention

W.T.E.: Waste To Energy

The technology enables the use of cheaper combinations of cheap fuels to produce energy. By burning all kind of pellets from food to vegetables and even cow shit the same way they are burned today but with the above savings.

Burning solids goes from carbon to medical waste if necessary where the only change is a direct flame of 1200º C at which needles, poisons and medical waste incinerate endothermically. Even if the purpose of the technology is to have cheaper exothermical reactions

Potentialities of the invention

Vortexes Effect

Out of the ejector there are 2 natural vortexes, outward rotation clockwise 80%, inward rotation anticlockwise 20% and one artificial vortex made with blades to support the outward final flow.

The combustion being sucked back by the inward 20% vortex, not only delays the outward flow, but makes an exquisite mixture of gases.

This makes this technology the only one with vacuum working inside the combustion chamber as a mixer and delayer.

Potentialities of the invention

Safety

100% Safe due to HHO production only on demand.

Also all its doubled safety features plus 2 more also invented

Potentialities of the invention

POWER PLANTS

Making power plants with these burners, using electric cars, and industries adapted has the capacity to fully clean a city in a short period of time after over 250 years of contamination.

Potentialities of the invention

DESALINATORS

Making high temperature Desalinators with HHO and natural gas, makes a fast and cheap Fresh water creation out of Sea water at about 40% of the cost today, achieving a very high production of Fresh water at a very low cost.

A flame of 1200º C evaporates about 33% more sea water that condensed, creates scarce Fresh water we all need.

Potentialities of the invention

SEA WATER AS FUEL

The process of evaporating seawater, condensing it in to fresh water, obtaining HHO through the hydrolysis and use it as part of the combination of fuels, turns sea water in to a affluent and ecologic fuel.

Potentialities of the invention

COST

The money saved, in the production of potable water as in the production of energy, is relative to the calories of the fuels to be used in the mixture. In all patents granted is a table in which it is estimated from 20 to 60% in certain combinations that include industrial waste. Using only natural gas, air and HHO, a saving of up to 80% is estimated with the appropriate burner model.

Cost savings proportionally increases fuel reserves.

Potentialities of the invention

Further advantages will be noticed sooner...

How does it work?

As a Two-Staged Vacuum Burner Reactor it can be described as:

The first stage being the suction and combustion chambers.

The second stage being the compression and expansion chambers.

Thus having 4 clear and different chambers:

Process in first chamber

The manifold works as a vacuum chamber. It includes all the gas suction valves that regulate natural gas, propane, butane, air, HHO and other gases. This chamber starts at the rear end and goes up to the tip of the nozzle of the ejector.

Process in second chamber

The combustion chamber can actually be visualized as an ejector with a diffuser where the gas at an approximate temperature of 300C is mixed with HHO to make a very concentrated flame of 1200C or 2200F.

Against this flame, liquid fuels are pulverized. Liquids are injected in the opposite direction to the exhaust flame and straight over the directing blades that produce a 3rd artificial vortex.

Process in third chamber

The compression chamber with a frustoconical piece and injectors, produce that molecules get closer, working as another nozzle that will create expansion and thus vacuum.

Process in fourth chamber

The expansion chamber, due to a previous compression that creates vacuum, has secondary air inlets providing oxygen flowing naturally as molecules are open to receive the necessary oxygen. HYDROGEN catches the outgoing or -running out- carbons, turning them into CH and so making lighter hydrocarbons easier to burn chains out of its difficult to burn longer chains of heavy fuels.

WorldWide Patents Legal Protection

Mixed Fuels Vacuum Burners Reactors

Discarded Patents

Mixed Fuels Vacuum Burners Reactors

World Corporations Discarded Patents by Inspectors

HUNTER

HITACHI, Ltd.

GENERAL MOTORS CORPORATION

GENERAL ELECTRIC COMPANY

GAS TURBINE EFFICIENCY SWEDEN Ab

Abb MANAGEMENT

WASTINGHOUSE ELECTRIC CORPORATION

ALSTOM

KOSO SEKIMOTO

GAS RESEARCH INSTITUTE

ALSTOM TECHNOLOGY Ltd

IGOR MATEEV

State Subsidiary Research and Testing Center of the Central Institute of Aviation Motors.

N METALL INST

KOREA ELECTRIC POWER CORPORATION

K.I.T.

Karlsruhe Institute of Technology (Germany)

Department of Chemical and Process Engineering

Engler-Bunte-Institute / Division of Combustion Technology

Prof. Dr.-Ing. Henning Bockhorn

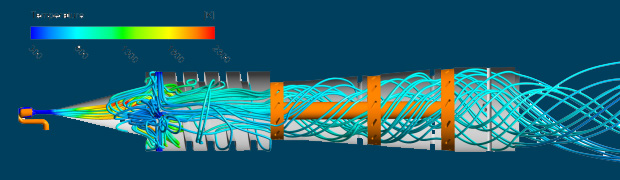

CFD: Computational Fluid Dynamics

CFI: Computational Fluid Investigation Reports

... Conclusions:

"The Mixed Fuel Vacuum Burners-Reactors process resembles a promising two stage or multiple stage combustion processes for the combustion of gaseous or liquid fuels for proving thermal energy from low grade fuels or the combustion of production wastes..."

See more in pdfs

Prototype

Mixed Fuels Vacuum Burners Reactors

Drawings

Mixed Fuels Vacuum Burners Reactors

Support

Mixed Fuels Vacuum Burners Reactors

Web Links

Mixed Fuels Vacuum Burners Reactors

CONTACT

About the Inventor

A life time creating solutions and solving marine engines problems.

For more than 40 years Jorge de la Sovera has been working as Chief Engineer for many of the Major Merchant Marine Navy and Cruise Lines Companies, around the world.

Since 1997 runs his very own company of ships and cruises projects and repairs, being vendor of companies as: Carnival, Norweigian, Disney, Celebrity, Royal Caribbean - Cruise Lines among others ...

Since 2008 he put focus in improving combustion process and reducing emissions to the atmosphere. The invention of this new technology, has been the result of years of experience, studies and practice.

Vision

Improving Blue Technological solutions for the planet in order to reduce emissions while reducing costs from enterprises to final users, and clean the few kilometers of atmosphere from which we all breathe and our descendants will inherit as our legacy.